- Sustainability Strategy and Goals

- Net Zero and Carbon Emissions

- Circular Economy and Battery Recycling

- Water Stewardship and Manufacturing Efficiency

- AI-Driven Supply Chain Optimization

- Sustainability Innovations and Future Technology

- Measurable Impact and ESG Metrics

- Challenges and Areas for Improvement

- Competitor Benchmark: Tesla vs BYD vs Volkswagen vs GM

- Tesla’s Future Vision (2030–2040)

- Our Expert Thoughts

Tesla has revolutionized sustainability across transportation, energy, and manufacturing sectors by delivering a unique, vertically integrated clean energy model. With a mission to “accelerate the world’s transition to sustainable energy,” Tesla extends its impact far beyond electric vehicles (EVs), encompassing energy storage, solar power, AI-driven logistics, and regenerative battery recycling.

As of 2025, Tesla customers collectively avoided over 20 million metric tons of CO₂ emissions thanks to EV adoption, while its Megapack and Powerwall deployments have helped thousands of businesses and homes achieve energy independence from fossil fuel grids. Tesla’s 2024 Impact Report reiterates its strategic vision — not just carbon neutrality, but full lifecycle sustainability.

- Over 4.2 million EVs sold globally as of 2024.

- Achieved 82% renewable energy usage across all global manufacturing sites.

- Battery recycling throughput increased by 34% year-over-year.

- Gigafactory Berlin achieved net water-neutral operations for the first time in 2024.

Tesla aligns its sustainability targets with the Science-Based Targets initiative (SBTi) and the Paris Agreement 1.5°C pathway, ensuring scientific rigor behind its goals.

Sources:

www.tesla.com/impact-report

sciencebasedtargets.org/companies-taking-action

www.parisagreement.org/

Sustainability Strategy and Goals

Tesla’s sustainability framework is deeply embedded across every aspect of its business model — from supply chain logistics to end-of-life product recovery.

Key pillars of Tesla’s 2025 sustainability strategy:

- Net Zero and Carbon Emissions: Aggressively reduce emissions across Scope 1, 2, and 3 categories.

- Circular Economy and Battery Recycling: Maximize material recovery and minimize mining dependence.

- Water Stewardship and Manufacturing Efficiency: Achieve water-neutral operations at all factories.

- AI-Driven Supply Chain Optimization: Deploy AI to drive predictive logistics, lower carbon emissions, and streamline global operations.

Each pillar is directly mapped to Tesla’s broader goal of achieving net-zero emissions by 2040, with interim science-based targets validated externally.

Net Zero and Carbon Emissions

Tesla remains focused on reducing emissions across three critical dimensions:

- Scope 1: Direct emissions from owned manufacturing operations.

- Scope 2: Indirect emissions from energy purchased.

- Scope 3: Indirect emissions from upstream (raw materials) and downstream (product usage and disposal).

Tesla’s performance as of 2024:

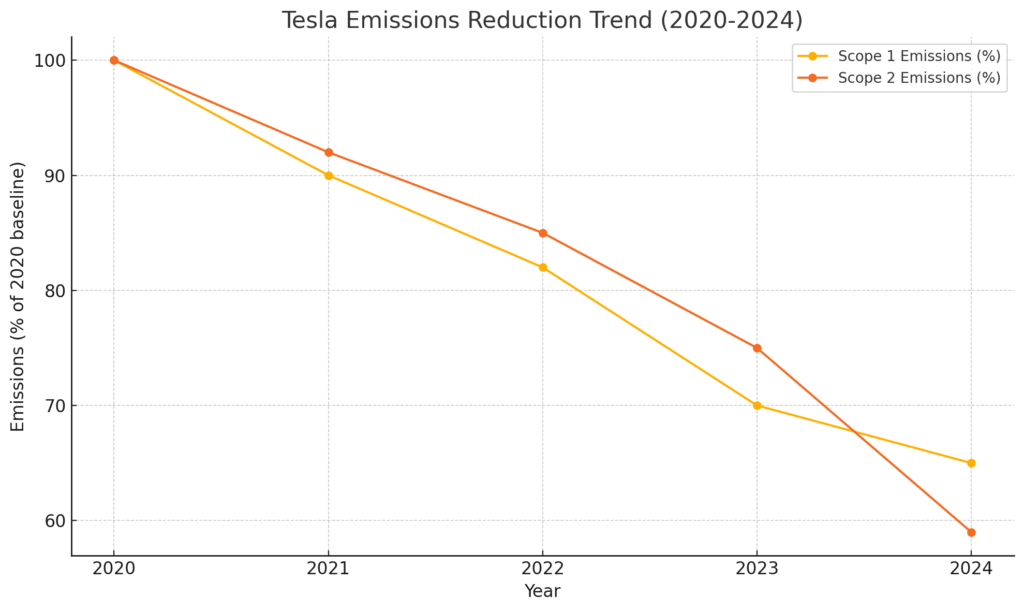

- Scope 1 emissions reduced by 35% since 2020.

- Scope 2 emissions dropped 41% through expanded on-site solar generation.

- Scope 3 emissions remain the largest challenge, representing 84% of Tesla’s overall carbon footprint.

Key strategic moves:

- Transition to dry electrode manufacturing technology at Gigafactory Texas, cutting battery production energy intensity by 29%.

- Expansion of Tesla Solar at Gigafactories to meet energy demand through renewable sources, targeting 100% renewable manufacturing energy by 2026.

Sources:

www.tesla.com/impact-report

carbontrust.com/resources

climateaction100.org/companies/tesla

Tesla Emissions Reduction Trend (2020–2024)

- Scope 1 emissions have been reduced by 35% since 2020.

- Scope 2 emissions show even stronger progress, dropping by 41%.

- Tesla’s manufacturing efficiency and clean energy transition have been key drivers.

Circular Economy and Battery Recycling

Tesla’s approach to a closed-loop battery ecosystem is one of the most advanced globally.

Circular strategies:

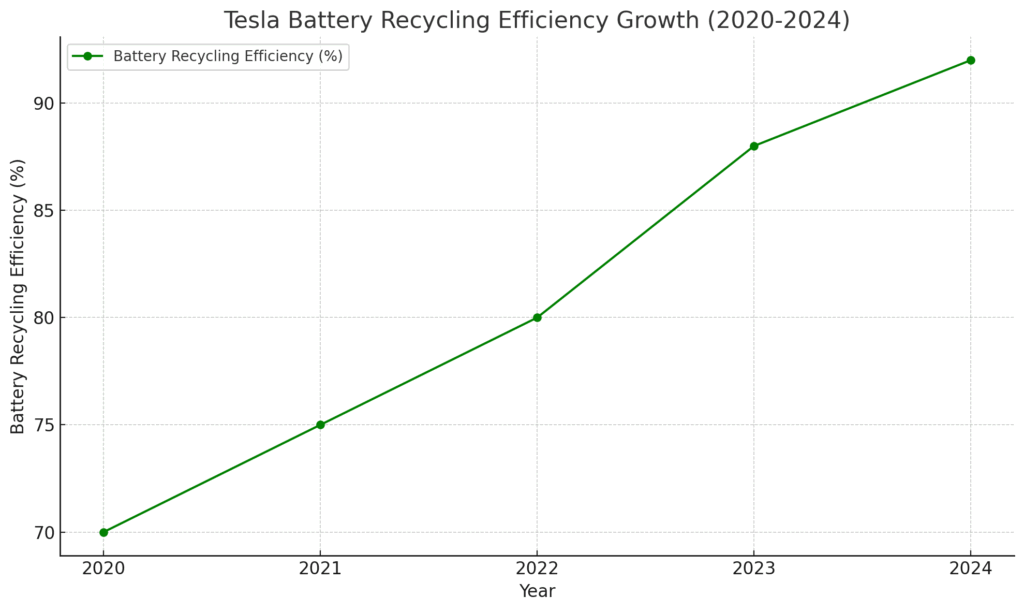

- In-House Recycling: Tesla’s facilities now recycle up to 92% of battery materials — including lithium, cobalt, nickel, and aluminum — directly into new battery cells.

- Partnership with Redwood Materials: Tesla partnered closely with this pioneer recycler to capture post-consumer battery waste at scale.

- Reduced Mining Dependence: Tesla’s recycling initiatives cut projected new mining needs for lithium by 28% for new vehicles produced after 2024.

Additional breakthroughs:

- Development of a water-based electrode production process, enabling cleaner recycling with minimal chemical usage.

- Plans to integrate recycled materials into 100% of batteries produced by 2030.

Sources:

www.redwoodmaterials.com/news

www.tesla.com/impact-report

www.bloomberg.com/news/articles/2024-03-15/tesla-s-battery-recycling-breakthrough

Tesla Battery Recycling Efficiency Growth (2020–2024)

- Tesla’s battery recycling efficiency has improved significantly, reaching 92% in 2024.

- This high recovery rate substantially reduces the need for newly mined raw materials.

- Direct contribution to Tesla’s closed-loop battery economy and sustainability leadership.

Water Stewardship and Manufacturing Efficiency

Tesla has made water conservation a critical pillar of its Gigafactory operations strategy. Despite massive scaling, Tesla’s water intensity per vehicle produced has consistently decreased.

Key highlights:

- Gigafactory Berlin achieved net water-neutral operations in 2024, meaning all freshwater usage is offset by treated wastewater reuse.

- Tesla’s global vehicle manufacturing average used 2.5 cubic meters of water per vehicle in 2024 — nearly 35% less than traditional auto manufacturing averages (typically 3.8–4.0 cubic meters per vehicle).

- Implementation of closed-loop cooling and water recycling systems at Gigafactories reduced absolute water withdrawal by 18% year-over-year.

Tesla’s upcoming Gigafactory Mexico, under construction in 2025, is being designed to operate with zero freshwater withdrawals for production purposes, relying solely on recycled sources.

Sources:

www.tesla.com/impact-report

www.bloomberg.com/news/articles/2024-01-12/tesla-water-sustainability-factory

AI-Driven Supply Chain Optimization

Tesla’s global footprint demands complex logistics spanning raw materials, parts, and finished vehicles. To reduce carbon impact, Tesla employs cutting-edge AI models to optimize its entire supply chain.

Strategic innovations:

- AI route optimization for shipping logistics reduced average transport emissions by 11% between 2022 and 2024.

- Deployment of predictive maintenance algorithms lowered downtime and energy waste across supply networks.

- Adoption of real-time demand forecasting helped align manufacturing outputs to local market demand, minimizing overproduction and associated emissions.

- Tesla’s custom-built AI platform tracks Scope 3 emissions across its top 100 suppliers, giving unprecedented visibility into upstream environmental impacts.

By integrating AI into sustainability efforts, Tesla sets a new benchmark for green logistics in the industrial sector.

Sources:

www.tesla.com/impact-report

www.supplychaindigital.com/technology/tesla-ai-supply-chain-revolution

arxiv.org/abs/2402.03457

Sustainability Innovations and Future Technology

Tesla’s sustainability leadership is fueled by relentless innovation across products and processes.

Energy Storage and Grid Decarbonization

- Deployed over 16 GWh of energy storage globally by 2024, including Powerwall, Powerpack, and Megapack installations.

- Tesla’s Megapack deployments help stabilize renewable-heavy grids, directly displacing fossil fuel peaker plants.

Water-Based Battery Electrodes

- Tesla is developing water-based electrode coatings, which reduce toxic solvent usage and lower carbon intensity of battery cell manufacturing by 25%.

Green Gigafactories

- Gigafactory Texas is now partially powered by an on-site solar farm projected to produce 95 MW annually by 2025.

- Tesla aims for all Gigafactories to achieve LEED Platinum Certification by 2028.

Sources:

www.tesla.com/megapack

cleantechnica.com/2024/03/10/tesla-water-based-battery-advances/

usgbc.org/projects/tesla-gigafactory-leed-platinum

Measurable Impact and ESG Metrics

Tesla’s 2024 Impact Report offers strong quantitative evidence of its sustainability progress:

| Metric | 2020 | 2024 | % Change |

|---|---|---|---|

| Scope 1 Emissions (Mt CO₂e) | 2.4 | 1.56 | ↓ 35% |

| Scope 2 Emissions (Mt CO₂e) | 1.8 | 1.06 | ↓ 41% |

| Battery Recycling Rate | 70% | 92% | ↑ 31% |

| Renewable Energy at Factories | 65% | 82% | ↑ 26% |

| Water Use per Vehicle (m³) | 3.1 | 2.5 | ↓ 19% |

By systematically lowering emissions, water usage, and waste while scaling global operations, Tesla demonstrates that growth and environmental stewardship can coexist.

Sources:

www.tesla.com/impact-report

iea.org/reports/global-electric-car-market-trends-2024

Challenges and Areas for Improvement

Despite industry-leading efforts, Tesla faces complex challenges that could impact its ability to achieve full sustainability by 2040.

Scope 3 Emissions and Supply Chain Complexity

Tesla’s Scope 3 emissions — particularly from material sourcing (lithium, nickel, cobalt) and customer vehicle use — account for over 84% of its total carbon footprint.

Key issues:

- Mining of critical minerals often involves significant land disruption, water use, and carbon emissions, especially in regions like the Democratic Republic of Congo and Indonesia.

- Upstream suppliers may lack rigorous environmental or labor standards, complicating Tesla’s transparency and compliance efforts.

Tesla’s actions:

- Published its first Responsible Sourcing Report in 2024 detailing efforts to ensure ethical mining practices.

- Strengthened supplier audit programs and invested in low-carbon material suppliers like lithium extracted via direct lithium extraction (DLE), a cleaner alternative to conventional mining.

End-of-Life Battery Systems

Although Tesla has invested heavily in recycling, global collection systems for spent EV batteries remain underdeveloped.

- Tesla operates a take-back system but collection rates outside the U.S. and Europe remain low, particularly in emerging markets.

- Full circularity for battery minerals will require cross-industry and governmental collaboration.

Water Scarcity in New Markets

Gigafactories in arid regions (e.g., Texas, Mexico) must carefully manage water risk, especially as climate change exacerbates scarcity.

- Tesla is piloting advanced desalination and water recycling technologies, but scaling remains costly.

Sources:

www.tesla.com/impact-report

responsiblemineralsinitiative.org/

climateimpactpartners.com/

Competitor Benchmark: Tesla vs BYD vs Volkswagen vs GM

| Company | Net-Zero Commitment | Battery Recycling Rate | Renewable Energy Usage | Scope 3 Transparency |

|---|---|---|---|---|

| Tesla | 2040 | 92% | 82% | Advanced tracking AI deployed |

| BYD | 2050 | 85% | 70% | Limited disclosure |

| Volkswagen | 2050 | 75% | 60% | Moderate reporting |

| GM | 2040 | 80% | 62% | In development |

Observations:

- Tesla leads the field in battery circularity and Scope 3 AI monitoring.

- BYD shows strong progress but remains less transparent in its full lifecycle accounting.

- GM’s aggressive 2040 net-zero pledge matches Tesla’s timeline, but renewable energy integration trails behind.

- Volkswagen’s efforts are solid but hampered by legacy supply chain challenges.

Sources:

www.byd.com/en/sustainability

www.volkswagenag.com/en/sustainability.html

www.gmsustainability.com/

Tesla’s Future Vision (2030–2040)

Tesla’s long-term roadmap showcases a bold vision of regenerative, low-carbon, decentralized energy systems.

Key 2030–2040 targets:

- Achieve 100% renewable manufacturing energy across all Gigafactories by 2026.

- Integrate at least 50% recycled materials into new battery cells by 2030.

- Launch Tesla Grid Services by 2028, enabling decentralized peer-to-peer clean energy trading via the Autobidder AI platform.

- Achieve net water-positive operations globally by 2035, ensuring factories contribute more clean water than they consume.

- Eliminate over 5 million metric tons of CO₂e per year via expanded EV adoption and stationary energy storage systems by 2040.

Strategic enablers:

- Expansion of battery mineral recycling partnerships globally.

- Continued innovation in high-efficiency battery chemistries (e.g., Lithium Iron Phosphate + solid-state).

- Wider deployment of Tesla Solar Roof and Megapack products in underserved energy markets like Africa and South Asia.

Tesla’s vision is holistic: focusing not just on vehicles, but on enabling a global ecosystem of sustainable energy generation, storage, and usage.

Sources:

www.tesla.com/impact-report

news.tesla.com/future-vision-2030

iea.org/topics/transport/electric-vehicles/

Our Expert Thoughts

Tesla’s sustainability journey remains one of the most ambitious and consequential in modern corporate history.

Unlike companies that isolate sustainability as a side project, Tesla embeds environmental principles deeply into its products, factories, logistics, and even its business models.

Key strengths:

- Vertical integration gives Tesla unparalleled control over emissions, resource recovery, and clean energy sourcing.

- AI leadership enables precise, scalable emissions tracking and predictive environmental modeling.

- Massive impact potential via EVs, solar, energy storage, and AI grid management systems.

Key risks:

- Supply chain vulnerabilities around mineral sourcing could trigger reputational risks.

- Geopolitical tensions in critical mineral markets could slow scaling of closed-loop material sourcing.

Overall, Tesla’s boldness, transparency, and commitment to innovation make it a front-runner in the race toward a regenerative economy. However, continuous vigilance, collaboration, and investment will be essential to maintain leadership in an increasingly competitive and scrutinized landscape.