BMW has firmly positioned itself as a leader in sustainable mobility, integrating advanced technologies to reduce its environmental footprint. Through a mix of electrification, AI-driven optimizations, and circular economy models, the company is creating a sustainable future for the automotive industry. The 2023 BMW Group Report highlighted their bold sustainability goals, with a target of reducing CO2 emissions per vehicle by 40% by 2030 compared to 2019 levels.

- Science-Based Targets Initiative (SBTi) backs BMW’s decarbonization strategies, ensuring they align with global climate action frameworks.

- BMW has focused on electric mobility, AI-driven manufacturing, and waste-to-energy technologies to drive environmental progress.

BMW’s efforts to reduce carbon emissions have been coupled with a commitment to creating 100% recyclable vehicles and engaging in sustainable material sourcing. Its circular economy approach is a central element of the company’s strategy, aiming for a closed-loop system that minimizes waste.

Sources:

BMW Group Report 2023

www.sciencebasedtargets.org/companies-taking-action

www.bmwgroup.com/sustainability

Circular Economy Models

A critical part of BMW’s sustainability strategy is reducing the dependency on primary raw materials by promoting a circular economy. The BMW i Vision Circular concept car epitomizes this vision, showcasing a fully recyclable vehicle constructed from 100% renewable and secondary materials.

BMW’s circularity strategy includes:

- Recycling materials: The company sources secondary aluminum and steel, drastically reducing the need for virgin resources.

- Closed-loop material cycles: BMW minimizes waste by repurposing manufacturing by-products, optimizing production efficiency.

- Vehicle end-of-life strategies: BMW ensures that dismantled parts and batteries are reintegrated into new products, maximizing the life cycle of materials.

Collaborating with suppliers and industry partners, BMW actively promotes sustainable material sourcing and recycling technologies to set new benchmarks in the automotive sector.

- BMW i Vision Circular: This fully recyclable car is a prototype of BMW’s sustainable vehicle manufacturing approach.

- The company’s closed-loop material initiatives aim to ensure that 50% of all vehicle components are recyclable by 2030.

Sources:

BMW Group Report 2023

www.bmwgroup.com/sustainability/circular-economy

Waste-to-Energy Technologies

BMW is taking significant steps to lower its environmental impact by integrating waste-to-energy technologies across its production sites.

Key Waste-to-Energy Projects:

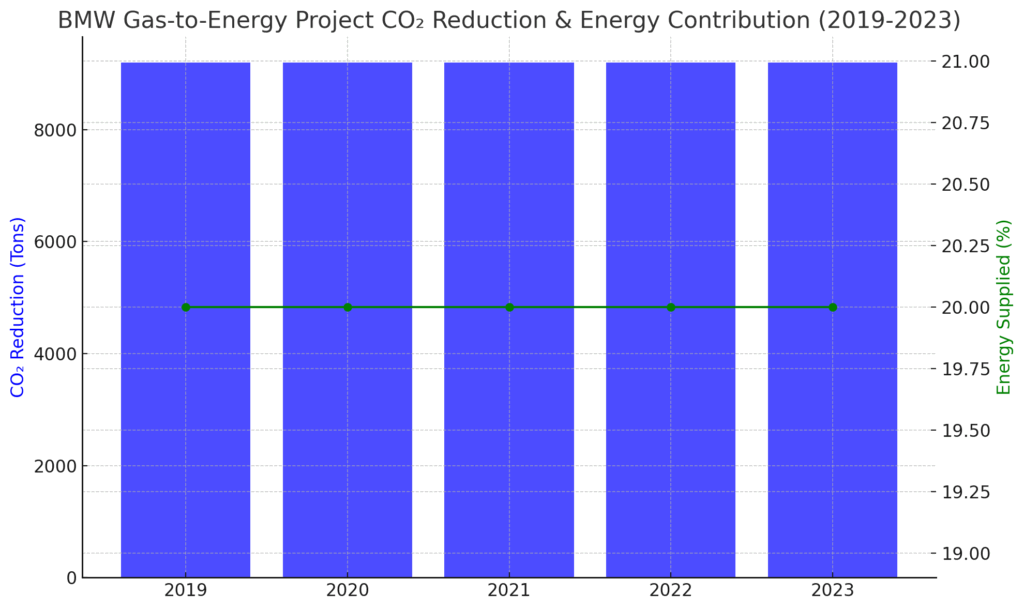

- Gas-to-Energy Project: Since 2003, BMW Manufacturing in Spartanburg, South Carolina, has been converting methane gas from the Palmetto Landfill into electricity and heat. This initiative generates about 20% of the plant’s total energy needs, reducing CO2 emissions by 9,200 tons annually.

- BMW has integrated solar power systems across its global plants, including the Leipzig factory in Germany, further reducing fossil fuel dependency.

- The company aims to achieve carbon-neutral facilities through the expanded adoption of renewable energy sources, including wind and solar.

BMW’s waste-to-energy initiatives directly contribute to its commitment to sustainable manufacturing, supporting its long-term decarbonization goals.

Sources:

www.bmwgroup.com/sustainability/energy

www.bmwgroup.com/sustainability/gas-to-energy-project

Data Visualization: CO₂ Reduction from BMW’s Gas-to-Energy Project

A visualize the CO₂ reduction from BMW’s Gas-to-Energy Project and its contribution to sustainability goals.

- The Gas-to-Energy Project has consistently reduced 9,200 tons of CO₂ annually.

- It supplies 20% of the energy needs at BMW’s Spartanburg, South Carolina plant.

- This project is integral to BMW’s strategy of decarbonizing its manufacturing operations and reducing reliance on fossil fuels

AI-Driven Supply Chain Optimization

AI is a cornerstone of BMW’s efficiency strategy, helping optimize production processes, reduce material waste, and enhance supply chain performance.

Key Benefits of BMW’s AI Integration:

- Production optimization: AI-driven algorithms optimize manufacturing schedules and material flow, reducing waste and improving operational efficiency.

- Predictive maintenance: AI enhances equipment lifespan by detecting potential issues before they lead to breakdowns, ensuring higher quality and lower environmental impact.

- Supply chain efficiency: Through AI, BMW predicts demand and adjusts logistics in real-time, improving the overall supply chain’s carbon footprint.

BMW has integrated over 600 AI-driven use cases across its global operations, significantly cutting material waste and energy consumption. This AI integration not only improves resource efficiency but also enhances production precision, reducing manufacturing defects and waste.

Sources:

www.bmwgroup.com/ai-supply-chain

www.bmwgroup.com/technology/ai-driven-efficiency

Key Sustainability Innovations and Technologies

BMW continuously pushes the boundaries of sustainable innovation by integrating renewable energy, circular economy principles, and AI-driven optimizations into its operations. Notable innovations include:

- BMW i Vision Circular: A concept for a completely recyclable car, aiming to minimize resource consumption and eliminate waste.

- Energy-efficient manufacturing: The Spartanburg Gas to Energy Project has cut 9,200 tons of CO₂ annually while providing renewable energy to the plant.

- Smart factories powered by AI: These factories have been optimized to reduce energy waste, ensuring high-efficiency production.

These innovations are pivotal in positioning BMW as a leader in green automotive solutions, setting new standards for vehicle production and energy efficiency.

Sources: BMW Group Report 2023

Measurable Impacts

BMW’s sustainability strategies are backed by measurable results that highlight the company’s commitment to environmental responsibility.

- CO2 emissions reduction: BMW has committed to reducing CO2 emissions per vehicle by 40% by 2030 compared to 2019 levels, ensuring alignment with the Science-Based Targets Initiative.

- Gas-to-Energy Project: The project has reduced 9,200 tons of CO2 annually, supplying 20% of the Spartanburg plant’s energy needs.

- AI-driven improvements: BMW’s AI initiatives have optimized supply chain efficiency, reducing waste and lowering energy consumption in production processes.

These improvements are significant, reflecting BMW’s commitment to integrating sustainability into its core business operations.

Sources: BMW Group Report 2023

Challenges and Areas for Improvement

BMW’s ambitious sustainability journey is making strides in decarbonization and circular economy practices, but like many leading companies, it faces several challenges in meeting its long-term goals.

High Energy Demands in Manufacturing

Although BMW has significantly reduced its carbon footprint, the energy demands of vehicle manufacturing remain high. To meet increasing global demand for electric vehicles (EVs), production must scale while simultaneously reducing energy consumption.

- Challenge: Manufacturing high-performance electric vehicles and batteries still requires significant energy input, especially in regions where grid power is not fully renewable.

- Solution: BMW plans to expand its use of renewable energy sources, like wind and solar, to power its global production sites. The company is on track to achieve 100% renewable energy by 2030, but this requires extensive infrastructure investments.

Third-Party Supplier Dependencies

BMW’s sustainability efforts are greatly impacted by its supply chain, particularly in sourcing raw materials for batteries. Much of the raw material extraction occurs in countries with limited environmental regulations, posing challenges for the company’s sustainability standards.

- Challenge: Some raw materials for batteries, such as lithium, cobalt, and nickel, are sourced from countries with weak environmental protections and social issues, including labor exploitation.

- Solution: BMW is increasing collaboration with its suppliers to ensure they meet sustainable sourcing standards. The company also partners with organizations like the Responsible Cobalt Initiative to improve labor practices and environmental standards in mining.

Consumer Behavior Impact

Despite BMW’s advances in creating sustainable vehicles, consumer behavior remains a significant barrier. The transition to electric mobility is hindered by factors like:

- High upfront costs of EVs,

- Limited charging infrastructure,

- Consumer hesitance to adopt electric vehicles.

- Solution: BMW has launched multiple incentive programs to reduce the cost of EVs and expand charging infrastructure. The company also plans to invest in second-life battery storage to promote further EV adoption and make EVs more accessible to a broader consumer base.

Scalability of Circular Economy Models

BMW has taken commendable steps toward a circular economy, but scaling this model across its global operations remains a significant hurdle. While the BMW i Vision Circular showcases innovation, the challenge is in mass adoption and integration of fully recyclable materials in production.

- Challenge: The sourcing of sustainable and recyclable materials is limited, and recycling technology has not yet reached the level required for large-scale production.

- Solution: BMW is investing in new recycling technologies and partnering with research institutions to develop more efficient systems for reusing critical materials and reducing the environmental impact of car production.

Sources:

www.bmwgroup.com/sustainability

www.responsiblecobalt.org

www.bmwgroup.com/circular-economy

Comparisons to Industry Competitors

BMW’s sustainability strategy is ambitious, but how does it compare to its competitors in the automotive sector? Here’s a look at how BMW stands relative to Tesla, Audi, and Mercedes-Benz:

BMW vs Tesla

- Tesla is a front-runner in zero-emission vehicles but has faced challenges in battery recycling and material sourcing, areas where BMW has made significant strides.

- Tesla’s carbon neutrality commitment by 2030 aligns closely with BMW’s decarbonization strategy, but Tesla lags behind BMW in circular economy initiatives, especially in vehicle recyclability.

BMW vs Audi

- Audi aims for a 30% reduction in CO₂ emissions per vehicle by 2025, a less aggressive target than BMW’s 40% reduction by 2030.

- Audi has adopted carbon-neutral production for its electric vehicle lineup but lags in integrating AI-driven supply chain optimization to the extent that BMW has done.

BMW vs Mercedes-Benz

- Mercedes-Benz aims for carbon neutrality by 2039 with its Ambition 2039 strategy, which is five years later than BMW’s 2034 target.

- Mercedes-Benz has yet to prioritize circular economy principles to the same extent as BMW, which is focused on 100% recyclable vehicles and closed-loop material use.

Competitive Edge

BMW’s AI-driven efficiency improvements, its focus on circular economy principles, and aggressive CO₂ reduction targets place it ahead of some competitors. Tesla remains the leader in electric vehicle innovation, but BMW’s holistic approach to sustainability (including waste-to-energy, recycling, and supply chain optimization) gives it a competitive edge.

Sources:

www.bmwgroup.com/sustainability

www.audi.com/sustainability

www.mercedes-benz.com/sustainability

Future Plans and Long-Term Goals

BMW’s sustainability roadmap for the next decade reflects its commitment to driving sustainable innovation and transforming the automotive industry.

Key long-term goals:

- Achieve 100% renewable energy in all production sites by 2030, ensuring that all BMW factories run on sustainable energy.

- Continue the expansion of electric vehicle offerings, with a target of having 50% of global sales be fully electric by 2030.

- Implement sustainable material sourcing across the entire supply chain, aiming to make 75% of vehicle materials recyclable by 2035.

- Scale battery recycling efforts, aiming for 100% of BMW batteries to be recyclable by 2035.

In addition to these ambitious goals, BMW is also working to ensure that its operations are carbon-neutral by 2034. The company plans to achieve these objectives through a combination of technological innovation, collaborations with eco-conscious suppliers, and expansion of renewable energy initiatives.

- Sustainable Mobility Solutions: BMW plans to expand its EV charging network by building fast-charging stations in key markets, making it easier for customers to switch to electric mobility.

- Sustainable Product Development: The company aims to use more sustainable materials in vehicle production, including increasing the percentage of recycled plastics and renewable materials.

BMW is setting new industry standards by combining innovation, renewable energy investments, and a focus on end-of-life vehicle management to create a future where cars are not only sustainable to drive but also sustainable to produce.

Sources:

www.bmwgroup.com/sustainability

www.automotiveworld.com/news-releases/bmw-group-long-term-strategy